The realm of 3D printing has revolutionized how we create and fabricate parts, especially in industries like automotive. A crucial aspect of this innovation is the filament used. In this post, we’ll explore six common types of 3D printing filaments – PLA, PLA Plus, ASA, PETG, ABS, and Nylon – and delve into their pros and cons, particularly their resistance to automotive chemicals and heat.

PLA (Polylactic Acid)

- Positives: PLA is one of the most popular filaments due to its ease of use and eco-friendliness. It prints at lower temperatures and doesn’t emit harmful fumes.

- Negatives: PLA’s lower melting point makes it unsuitable for high-temperature applications. It’s also not very resistant to automotive chemicals.

- Automotive Suitability: PLA is great for prototyping but less ideal for parts exposed to high temperatures or harsh chemicals.

PLA Plus (PLA+)

- Positives: PLA+ offers the same eco-friendliness as PLA but with added strength, better layer adhesion, and slightly improved heat resistance.

- Negatives: Like PLA, it still struggles with high temperatures and chemical resistance.

- Automotive Suitability: Better for end-use parts than regular PLA, but still limited in high-temperature or chemical-intensive environments.

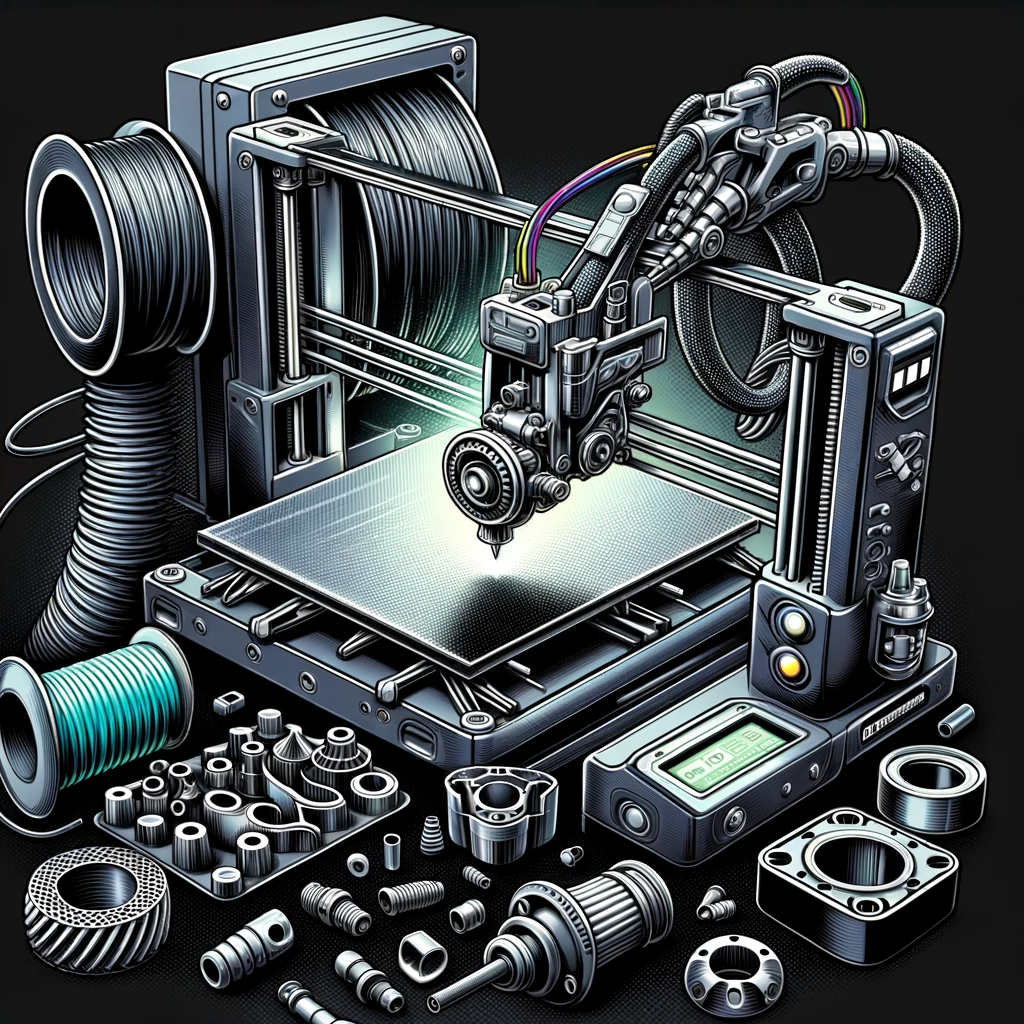

ASA (Acrylonitrile Styrene Acrylate)

- Positives: Known for its UV and weather resistance, ASA is great for outdoor applications. It also shows good chemical resistance and durability.

- Negatives: It requires higher printing temperatures and can be prone to warping.

- Automotive Suitability: Excellent for external automotive parts exposed to sunlight and weather.

PETG (Polyethylene Terephthalate Glycol)

- Positives: PETG combines ease of printing with strength and chemical resistance. It’s also somewhat heat-resistant.

- Negatives: Can be sticky during printing and is prone to stringing.

- Automotive Suitability: A versatile choice for both interior and exterior parts, balancing ease of use with durability.

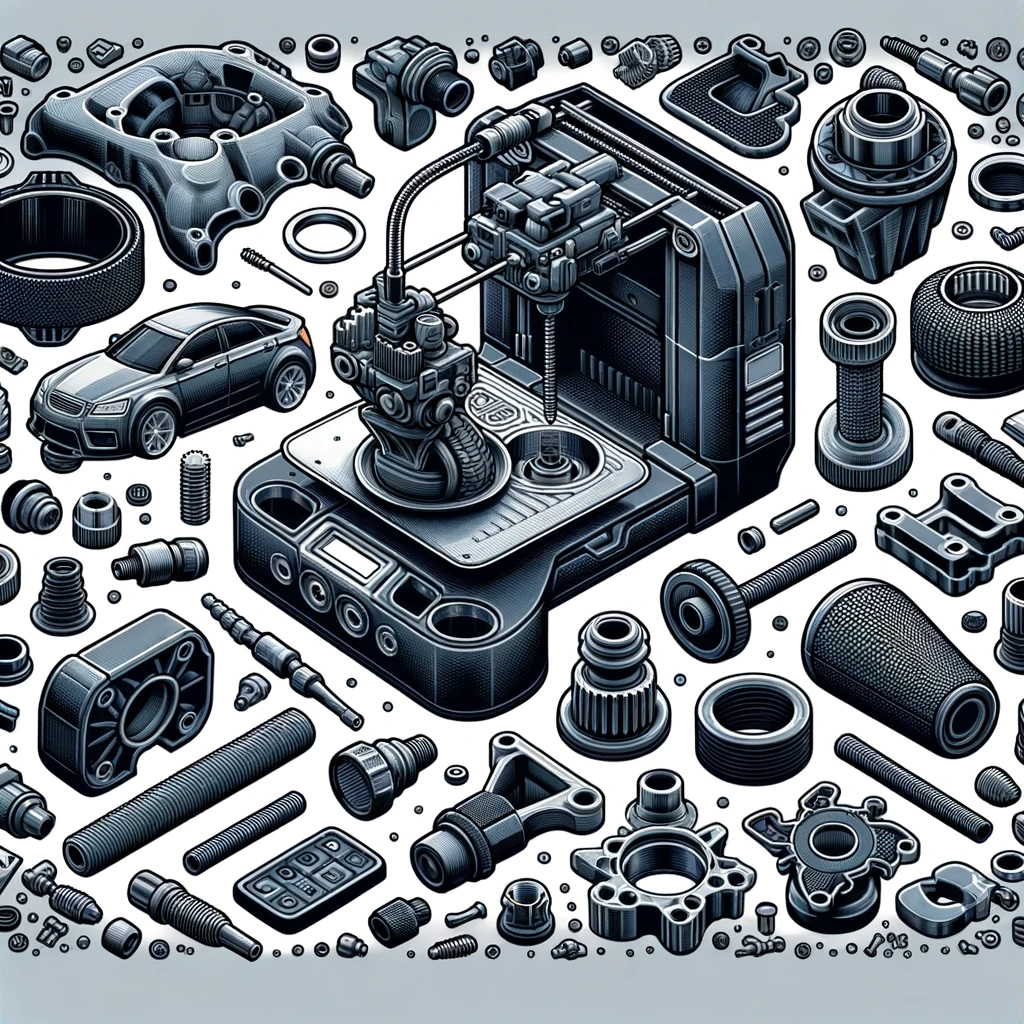

ABS (Acrylonitrile Butadiene Styrene)

- Positives: ABS is known for its strength, heat resistance, and durability. It’s a popular choice for functional parts.

- Negatives: It emits fumes during printing and requires a heated bed to prevent warping.

- Automotive Suitability: Ideal for high-temperature applications and parts that need to resist wear and tear.

Nylon

- Positives: Nylon is incredibly strong, durable, and flexible. It has good chemical and heat resistance.

- Negatives: It absorbs moisture from the air, which can affect printing quality, and requires high printing temperatures.

- Automotive Suitability: Great for parts under mechanical stress or those needing flexibility and heat resistance.

Conclusion

Each filament type offers unique advantages and challenges, particularly in the context of automotive applications. Your choice will depend on the specific requirements of the part – whether it needs to withstand high temperatures, resist chemicals, endure mechanical stress, or face environmental factors. By understanding the properties of each filament, you can make informed decisions to optimize your 3D printing projects in the automotive field. PLA will be the cheapest to print so it is perfered if prototyping. Any 3d print that is custom ordered are as is.